high temperature creep metals|stress vs larson miller parameter : bulk Metals. Metals often experience creep in high-temperature applications, such as power plants and aerospace components. The creep behavior in metals is influenced by their . Se você quer saber sobre os lançamentos de plataforma nova em primeira mão clique abaixo e saiba os lançamentos diários. https://plataformanova.com.br/. Escolha algum dos Slots da PGslots que estiverem com porcentagem pagante acima de 90%, Faça o seu cadastro e apostas antes da redução dos percentuais que.

{plog:ftitle_list}

CIBELLY FERREIRA. PROMOÇÃO. 😍 Conteúdo Amador. 🔥 Completo no GRUPO VIP. 💰 Valores: 🔥 20,00. ⚠️ Entre em contato e chame já @alaneprive. 🚀 ACESSO LIBERADO .

Metals. Metals often experience creep in high-temperature applications, such as power plants and aerospace components. The creep behavior in metals is influenced by their .High-temperature creep of metals is characterized by the fact that in the body, along with the accumulation of irreversible creep deformations, the formation and development of defects . The deformation rate at the stationary stage defines the creep strength of a material. The materials used in high-temperature applications should have high corrosion resistance, oxidation resistance, and creep strength. Creep of crystalline materials at high temperatures is a thermally activated process and is governed by the mobility of point or line defects. Shear or sliding in the grain-boundary regions introduces additional complexities to the creep of polycrystalline materials at elevated temperatures.

The title the Editors selected for the Special Issue of Metals —“Creep and High-Temperature Deformation of Metals and Alloys”—underline common features between them. 2. Contributions to the Special Issue . The Special Issue, “Creep and High Temperature Deformation of Metals and Alloys”, includes papers covering in innovative ways . Climb-Controlled Creep in Pure Metals At high temperatures the rate of creep of most metals and many solid solution alloys is controlled by the recovery of the dislocation substructure. When the temperature is high enough, in excess of from 0.55 to 0.7 of the melting point 7^, dislocation climb appears to be the rate-controlling re covery .

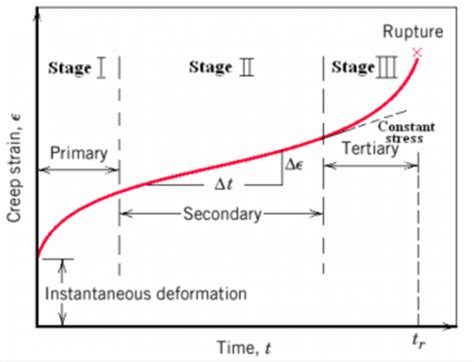

Creep is a major concern, since it can cause materials to progressively deform, and possibly to fail, under applied stresses below their yield stress. . Have an appreciation of the mechanisms involved in creep deformation, and their general dependence on temperature and stress; Understand what is meant by Primary, Secondary and Tertiary Creep .

Creep is the time-dependent plastic deformation of a metal or material under load. Creep usually occurs at high temperatures but can also occur at room temperature. Good examples are lead or glass. The concept of high temperature varies from material to material, as one temperature is high for one material, but not high for another material. Creep and Creep Rupture of Metals is devoted to the fundamental description of the phenomenon of creep which occurs widely in high-temperature deformation of metals. The same conclusion obtained from creep experiments of nc-metals have been confirmed by many researchers [34, 43, 44]. . It is known that the high-temperature creep of aluminum follows the Arrhenius equation, and the strain rate can be written as (7) . Creep and fatigue are the most prevalent causes of rupture in superalloys, which are important materials for industrial usage, e.g. in engines and turbine blades in aerospace or in energy producing industries. As temperature increases, atom mobility becomes appreciable, affecting a number of metal and alloy properties. It is thus vital to find new characterization .

Abstract. The steady-state, time-dependent plasticity, or creep, at high and intermediate temperatures of pure metals, type M alloys, and many ceramics and minerals over a fairly wide range of stress, that usually comprises conventional creep regimes, follows a classic 5-power-law behavior and power-law breakdown that is illustrated here. Although laboratory-scale development of novel metals and alloys has been rapid, high-quality creep data remain rare for new materials, e.g., refractory element-based alloys and metal matrix composites. . Very high temperature creep properties of twelve different Ni-based single crystal superalloys have been investigated at 1250 °C and under . The second one is creep, which represents the most important mechanical issue for the systems operating in high-temperature environments. Creep occurs when the material is loaded, even if at low constant stress level, and produces the irreversible (plastic) deformation of the material at an extremely low but inevitable strain rate .Temperature Impact on Creep in Metals Temperature plays a significant role in the progression of creep in metals. Higher temperatures facilitate increased atomic movement, enhancing the rate of creep deformation. . Oxidation and Corrosion: At high temperatures, metals are susceptible to oxidative and corrosive environments, resulting in .

During high-temperature creep, Re is easily expelled from the γ′ phase under high temperatures and applied loads, increasing the diffusion ability of other elements and resulting in KW being activated again to slip on the {111} plane, which is the main reason why the alloy containing only Re retains less of a KW lock under high-temperature .

J. Stoop and P. Shahinian, “Effect of Oxygen on Creep-Rupture of Niobium”, High Temperature Refractory Metals, Part 2, AIME Metallurgical Society Conferences, Volume 34, 1966, pp. 407–432. Google ScholarGarofalo F 1965 Fundamentals of Creep and Creep-Rupture in Metals (New York: Macmillan) Google Scholar Kennedy A J 1962 Creep and Fatigue of Metals (Edinburgh, London: Oliver and Boyd) Google Scholar McLean D 1962 Deformation at high temperatures Met. Abstracts 1 481 . Google Scholar. Export references: BibTeX RIS Metals. Metals often experience creep in high-temperature applications, such as power plants and aerospace components. The creep behavior in metals is influenced by their crystalline structure and alloying elements. Nickel-based superalloys, for example, resist creep at elevated temperatures, making them ideal for turbine blades. To precisely characterize high-temperature creep behaviour of metals and alloys, considerable efforts have been made to obtain a fundamental understanding of the creep mechanism and to develop creep constitutive models , such as the power law equation applied to describe the behaviour of materials up around 1500 °C, the continuum damage .

The physics of high temperature creep in metals 3 engineers towards higher and higher temperatures in this and all other kinds of engine-internal combustion engines, nuclear reactors, rockets, etc.-and the problem of keeping pace, by producing alloys that neither deform too much nor fracture when under load at these high temperatures, is a . This type of creep tends to dominate over Coble creep at relatively high temperature, and with large grains or single crystals. . particularly in metals, where dislocation densities tend to be high. Provided the stress is below the yield stress, conventional macroscopic plasticity, occurring predominantly via dislocation glide, should not . High-temperature processes induce creep and corrosion, primarily resulting in failure of thin-walled pressure vessels. Investigating alloy creep behavior in these vessels is crucial due to its often undetected nature, leading to sudden and costly failures, posing irreversible risks to health and the environment. This study investigates the creep behavior of . This chapter presents a comprehensive review of the creep technique used for the study of defect structure and diffusion in metal oxides, both single crystals and ceramics. At high temperatures, the creep rate is proportional to the diffusion coefficient of the slowest species in solid compounds, whatever deformation mechanisms are present (Nabarro viscous creep, .

The aim of this paper is to present a systematic study on high-temperature creep and post-creep response of structural steels. A wide range of stress levels (0.4‐1.1 of the yield strength) was adopted to span all possible loads when conducting creep tests at temperature range from 300 to 800 °C. Materials Science and Engineering, 77 (1986) 1-18 1 Review Paper Dislocation Structure in the High Temperature Creep of Metals and Solid Solution Alloys: a Review ALENA ORLOV/~ and JOSEF ~ADEK Institute of Physical Metallurgy, Czechoslovak Academy of Sciences, 616 62 Brno (Czechoslovakia) (Received March 7, 1985) ABSTRACT The present .

High-temperature creep tests of additively manufactured (AM) and wrought nickel alloy 718 (IN718) were conducted at 650 °C and 704 °C at stresses ranging from 316 to 819 MPa. The AM alloy had a greater creep strength than the wrought alloy at nearly all testing conditions due to increased volume fractions of γ” in the matrix and carbides .

HIGH TEMPERATURE CREEP AND FRACTURE BEHAVIOR OF THE REFRACTORY METALS By R. T. Begley, D. L. Harrod and R. E. Gold The creep properties of the pure, polycrystalline refractory metals are . behavior of the refractory metals, the high melting transition metals in Groups VA (V,Cb,Ta) and VIA{Cr,Mo,W) of the periodic table. No attempt is made to .

Creep test measures the progressive rate of deformation of material at high temperature. For metals, most creep tests are conducted in uniaxial tension (3). When the change of length of specimen .

spigen ultra hybrid iphone se drop test

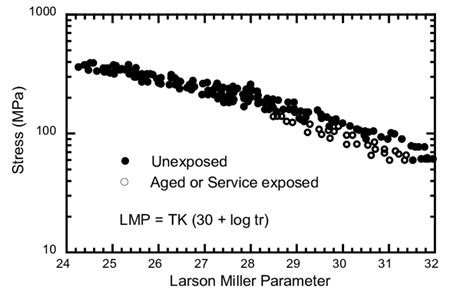

stress vs larson miller parameter

phenomenon of creep

WEBO CooMeet é uma plataforma on-line onde você pode se conectar e conversar com mulheres incríveis. Ela oferece a oportunidade de bate-papo por vídeo ao vivo com pessoas que compartilham interesses semelhantes. No CooMeet, você pode fazer novos amigos ou até mesmo encontrar sua alma gêmea, que você tem procurado todo esse .

high temperature creep metals|stress vs larson miller parameter